With solders...

![]()

PLEASE, BEFORE YOU PERHAPS WISH TO PRINT THIS FILE ASK YOURSELF IF YOU COULD POSTPONE THAT THOUGHT !

IT MIGHT STRIKE YOU AS SMALL AND SYMBOLIC GESTURE FROM YOUR BEHALF, BUT EVERY ACTION COUNTS. WE MUST START FROM SOMEWHERE !

PLANET THAT IS OFTEN CALLED AS WATER PLANET IN 2006. HAS 3% OF DRINKABLE WATER (NO TYPO) ISN'T THAT IRONIC?

WE NEED AIR EVEN MORE THEN WATER, CONSIDER THAT EVERY PAPER SAVING ACTION CONTRIBUTES TO LESS PAPER CONSUMPTION, THUS THREES AS SUCH !

RESPONSIBILITY IS THE ESSENCE IF YOU CONSIDER NEXT GENERATIONS, THOSE OF YOUR OWN KIN, YOUR CHILDREN, THOSE THAT INHABIT THE WOODS : ANIMALS.

SO READ THIS SCREEN IN NORMAL 030 MODE OR SAVE IT AS WEB PAGE ON YOUR OWN OS MACHINE.

You have now in your hands the most polished item proposed for the Falcon. The CT60 took many months of conception, design, tests and the 'know-how' of several persons. It is why I want to thank you very much for your support all during the development. Without this support, the CT60 wouldn't exist !

To fitt your CT60 with solders, read carrefully this documentation through the end before starting anything. So if you don't feel confident in doing it yourself, don't even start. Just contact me to agree on the shipping of your mother board and installation of your CT60. ATTENTION : If once installed and have checked your work several times, your Falcon still doesn't work, I will have to decide, in all honesty, if the problem comes from your first try or not.

Précautions

Many components of the CT60 are sensitive to static electricity: avoid touching the card and especially the pins of the components and connectors. Hold the card by the edges. Please make sure your body is discharged of static electricity, example, touch a metallic object that is in contact with the ground (faucet for example), the best would be to touch a metal chassis (without paint) of an electrical appliance connected to the ground (toaster for example). Be careful with carpets and synthetic clothes... Don't walk barefoot on the carpet.

Warranty

The CT60 is warranted. However I can reduce or even cancel this warranty if the product hasn't been used or handled correctly.

Tools

- Phillips screwdriver.

- Thin flat pair of pliers.

- Soldering iron, 30 to 40 Watts, with very thin tip and connected to the ground (!) Make sure the outlet you use has a ground, and this ground wire is really connected to the ground. If you don't own the place, don't trust what you might see if you undo the cover of your electrical outlet. You may destroy one or several chips of your beloved Falcon if you use a soldering iron without ground. (except some high end soldering iron equipped with an anti-static system).

- Good tin solder, 60% tin and 40% lead.

- Small utility knife with a new blade.

- Transparent adhesive (scotch-tape).

And eventually:

- Pair of pliers (very thin) to cut electric wires.

- Pair of pliers to strip the wires insulation off.

Not furnished material

- SDRAM DIMM PC100 or 133 from 64 to 512 MB (see the table on the web site to choose).

- If you don't use an ATX TOWER :

- ATX Power Supply (with an AC ON/OFF switch is better).

- Femal 2 pins connector (HE13/14), 2 wires & push button to control the ATX power supply.

- If you want to turn OFF the CT60 with something else than a simple jumper :

- Femal 2 pins connector (HE13/14), 2 wires & lever button two positions (ON/OFF).

If you can't find the HE13/14 connectors, don't solder wires on the pin of the CT60 ! Let them clean ! Solder the 2 wires under the PCB on the solders of the connector; it's so better...

Compatibilité

ST-RAM CARDS : The following models don't run with boosted F30 bus from 20 MHz :

- CENTram II (4 SIMMs)

- Falcon Wings (4 SIMMs)

- Atari 14 MB card (16 chips)

Please find an other ST-RAM card or fitt the CT60 without solders.

The CT60 should run fine with some motherboard boosters at 20 or 25 MHz. But the CT60 is designed to use a Falcon bus at 16 and 25 MHz and offers so the same possibilities with some solders ! It is recommended to not use an old booster with CT60. Contact me if you need me to remove the old booster...

ATTENTION : At 25 MHz, VIDEL is accessing very fastly the ST-RAM ! Some 14 MB ram board have too long trace and you will see bad pixels on the screen especially in 256 colors modes. The 060 & SDMA accesses will not be corrupted by this problem because they add a wait state cycle. The BLITTER may read corrupted data like VIDEL; it is not important if the data are only for screen BUT if the data are for somewhere else, you may crash !!

With a 60ns SIMM, all the following cards get little or important problems on the screen. The bad pixels may be very rare up to very present as vertical lines, essentially depending of the quality of the SIMM :

- CENTram 14 (FR)

- MegaRAM 14 (FR)

- Action Soft (UK)

- Hard & Soft PS2-RAM (D)

- Wizztronics Falcon Memory Up-Grade (USA)

- Paskud (PL)

Thermic aspects

The CT60 is equipped with heatsink + fan.

If you bought the CT60 with the 060, the heatsink is stuck to the CPU with thermical glue.

If you bought the CT60 without the 060, you have first to plug the 060 on the PGA socket of the CT60. See the photo below for the correct position. If you do not insert correctly the 060, it will burn ! After you have to stick the furnished heatsink on your 060. Last, it is an absolute necessity to use thermical glue or the 060 may be dammaged by strong warming.

There is no system to fix the fan on the heatsink. I suggest you to use a double side adhesive ruban between one border of the fan and the SDRAM DIMM or simply glue the fan on the heatsink.

ATENTION : the fan must blow on the heatsink, this means the sticker of the fan must be UNDER and not viewable when the fan is positionned !

Orientation

The instructions and other placement indications are to be visualized and followed as if the mother board was in front of you, as if you were using the computer (in the origin case).

Undoing the Falcon

Flip over the machine, undo the 7 screws from the case and the 3 long ones from the floppy drive. Flip the machine over again and remove the case. Undo the power supply cover screws. Undo this cover. Disconnect the floppy drive power. Undo the 2 screws from the legs of the power supply, then remove the power supply along with the connector. Undo the screws of the cover remaining (all along the mother board), you will then bend the little tips straight up in order to remove this cover. Disconnect your memory card.

Preparing the mother board

With the thin cutting pliers or utility knife, cut then bend up slightly the pins 3 and 4 of the ACIA 68B50 (U24) near the MIDI sockets, same operation for the keyboard ACIA (U52) close to the left of the keyboard connector.

Verify you see no 74F08 soldered (added) on the clock trace near the SDMA chip. If yes, you must remove this 74F08 and connect again the clock trace (that was cutted for this 74F08).

- If you see a component 74F08 or 74F04 on the GAL U63 (left of the NVRAM) with some wires connected on the resistor places R216, R217, R221 & R222, you must remove this component and the wires. Solder the three 33 ohms SMT resistors (furnished) on R216, R221 & R222 places.

- If you have no 74F08 or 04 on U63, you have to verify all the three resistors R216, R221 & R222 are well 33 ohms marked 330 or 33R). On some motherboards, one of them can be a 0 ohm (marked 0 or 0R0) : replace it with a 33 ohms.

Cut as close as possible to the mother board the left pin of L102 which is located next to the NVRAM. Bend it 45° rear and tin it.

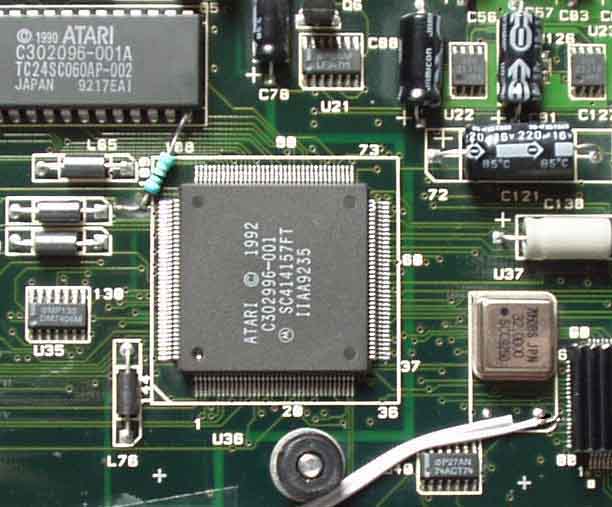

Locate the DSP (U38) under the floppy drive place. Cut the track that goes from the (big) hole far right of the 32MHz clock (U37) (left of DSP) to the DSP. (see picture). The cut has to be as near as possible of the hole, and the length has to be at least 1/2 mm. On the right side of the track, scratch the varnish (2 mm long) then tin it.

Locate the SDMA (U36) under the floppy drive place. Locate the Clock trace arriving the the second pin from the left/rear corner (see the photo). Scratch the varnish (2 mm long) until you reach the metal, then tin it. Solder the 47 ohms (yellow, purple, black, gold) resistor (furnished) between the pin #14 of the AJAX chip (U20) and the clock trace like on the picture. The resistor must be closest to the SDMA and the pin soldered on the clock trace must be the shortest possible : it is termination resistor.

TOS Chip

Verify the access time of your TOS chip (below the ST-RAM card). Remove the right border of the sticker. You should read a -10 or -12 or -15 corresponding to 100, 120 or 150 ns.

If you have a 150ns chip, you have to modify the solder jumpers of the U46 place. U46 is at the left border of the mb between the cartridge and joystick ports. The (default) setting you should see is, reading from left : ON OFF OFF ON... with ON that is a solder jumper. Modify the 3rd and 4th points to set ON OFF ON OFF. Do nothing if you have a -10 or -12 chip.

32MHz CLOCK for VIDEO modes ?

This clock is sent to the EXT pin of the VIDEL (pin #14).

For RGB and ST-Mono modes you need a new 32 MHz clock because the origin 32 MHz clock will be now a 40 or 50 MHz. More, if you have a old NON-Multisync VGA monitor, you will have some problems to set some extended video modes with a 40 MHz and worst a 50 MHz clock. A 32 MHz clock is ideal for such old VGA monitors.

Locate the video chip 'VIDEL' (U34). Locate the pin #14, counting to the left from the right back side. In front of this pin, there is a metallic hole connected to this pin. With the tip of the utility knife, scratch the varnish until you reach the metal, then tin it. Be Careful with the videl. Solder a short cutted pin of a 33 ohms classic 1/4 W resistor (not furnished) into the right forward hole of the oscillator U37 (see DSP picture above). Solder a single thin wire from the resistor to the hole of the videl pin #14. This wire must be as short as possible and above the motherboard. For this place the wire on forward border of the floppy motherboard connector and fix it with adhesive.

If you have the gray ATARI VGA adaptor, the extended video VGA modes with the 32 MHz clock on pin #14 won't be possible with this atari VGA adaptorout modifying this adaptor (which is bugged !). You need to flip it and cut with the utility knife into the plastic, a 1cm wide strip on the whole length and at 4mm of the metallic border. After this you can access the inside, you separate the pin 15 from the pins 11 and 19. Move aside the 2 wires connected to pin 15, cut them as close as possible to the pin and connected them together. If you don't want to do this hack, you can get 2 DB19 (male and female) that you will solder (direct cabling) without connecting the pin 15 (cut them). This little adaptor will be inserted between the Falcon VGA port and the gray ATARI VGA adaptor.

32MHz 68882

If there is a FPU 68882 in the socket (under the old Falcon PSU place), the clock from the motherboard must be no more used. This clock is on the pin#11 or #2 counting from left top corner to left bottom corner,

This is important for SDMA clock !

The new FPU clock is taken from the DSP 32 MHz OSC, as explained above for Videl and it is practical to add a wire from this Videl pin#14 to the FPU. The FPU clock modification can be done by two ways :

The better but the most difficult is to cut the clock trace under the socket as on the picture below. For this, remove (cut) a small part of plastic to access the trace and cut it. Remove the vernish on the left small trace and pass a thin wire between the socket and the board, between two pins. You have just now to solder the wire.

The less difficult but not perfect way is to put a small adhesive on the socket pin and put the wire between the adhesive and the FPU pin when plugging this last one.

And be carefull to not break the socket when unplugging the FPU !

Pre-fitting of the CT60 for the ribbon cable

To well place the ribbon cable, you have to place momently the CT60 on the motherboard slot. Remove the jumper on this slot and keep it. Place the card over the slot bus first to see if all is aligned correctly. Then apply a light pressure, light because you will have to extract the board later...

Ribbon cable

Some signals are grouped by par, one signal and one ground that must not be separated with the signal !

Ribbon cable connector pinout (pin #1 at corner of the CT60) :

10 = not used

9 = Pin #8 of U63

8 = DSP CLOCK Ground

7 = DSP CLOCK

6 = ACIA-Midi CLOCK

5 = ACIA-Keyboard CLOCK

4 = 32MHz CLOCK (from mb)

3 = 32MHz CLOCK Ground

2 = CT60 CLOCK (to mb)

1 = CT60 CLOCK Ground

Place the ribbon cable on a piece of a hard cardboard, and separate using the utility knife the wires until the connector keeping together (do not separate) :

- #1 & #2

- #3 & #4

- #7 & #8

The other wires are alone (separated).

Cut the wire #10 at 3 cms of the connector (this wire is not used this time).

Plug the connector in the male connector of the CT60.

From here, you have to put the wires on their correct position & way (see photo) and fix them with adhesive on the mb (the long wires).

Cut & solder the wires of the ribbon cable starting by the #1. You must cut the wire just the good lentgh to allow soldering without excess of wire. Cut the GROUND wires 1/2 cm shorter and do not strip the insulation (no soldering for them) :

Wire #2 on left PCB pad of L102.

Wire #4 on left pad of L102.

Wire #5 on pins #3 & #4 of the Keyboard ACIA.

Wire #6 goes under the CT60 and you will solder it at the end on pin #3 & #4 of the ACIA Midi.

Wire #7 on DSP clock trace (the right part of the cut).

Wire #9 on pin #8 of the GAL U63.

Be careful in not having wires crossing (especially near the connector), the ideal would be to have all the wires parallel to each others.

When all wires, except #6 are soldered and fixed, you have to diconnect the ribbon cable and unplug the CT60 to fix this last wire on the mb like on the photo.

FOLLOW THESE RULES:

- Don't EVER make a loop with a wire like for example going around a component's leg.

- Don't cross together the wires anywhere (except for wires #6 and #9).

Stay as straight as possible and keep the most important distance between each wires: a wire disturbs the others and is disturbed by the others.

Definitive plugging of the CT60

Insert your DIMM module on the CT60.

Insert the CT60 on the Falcon bus. For this you need to place the card over the bus first to see if it is aligned correctly. Then apply an equal pressure with your left thumb on the solders of the left female connector and your right thumb on right female connector in order to fully insert the CT60. Attention: don't apply pressure on any of the CT60 components.

Insert the connector of the ribbon cable.

Connect the Floppy power connector coming from the mb on the CT60 4 pins connector at the right rear corner. ATTENTION : respect the colors indications : the wire RED with the pin indicated 'RED' on the board and same thing for the BLUE. Inverting the connector here will DESTROY THE MOTHER BOARD at POWER ON !

Connect an ATX power cable to the Floppy power connector.

Connect the ATX power cable on the ATX power connector of the CT60.

Move the JP1 Jumper (near the 66 MHz oscillator) on the position 'F30 BOOST'. Later you will be able to set back to a 16 MHz falcon bus by moving back this jumper !

If you have a tower, connect the front tower wires (POWER ON/OFF and RESET push buttons, Power LED & IDE LED).

Eventually, connect a switch CT60 ON/OFF (you can use the jumper from the slot to go back to 030 mode).

CT60 connector pinout (pin #1 at left) :

1 = ATX POWER Switch

2 = ATX POWER Switch Ground

3 = CT60 ON/OFF Switch

4 = CT60 ON/OFF Switch Ground

5 = IDE LED +

6 = IDE LED -

7 = RESET Switch

8 = RESET Switch Ground

9 = POWER LED +

10 = POWER LED -

11 = POWER LED -

12 = JTAG_VCC

13 = JTAG_GND

14 = JTAG_Key

15 = JTAG_TCK

16 = JTAG_TDO

17 = JTAG_TDI

18 = JTAG_TMS

Never connect something on the JTAG pins, except the JTAG download cable (see schematic on the web site update area). The LED don't need serial resistor : already on the CT60. The ATX POWER & RESET buttons must be PUSH buttons like on the ATX Towers.

The installation is done. Put the machine back together and boot it.

Some problems to solve (after you updated the ABE & SDR chips) :

-

You hear some audio CRACs when running SDMATEST (2KB) at 50 KHz with 4 tracks.WORK AROUND : Solder a 27 pF capacitor parallel on the 47 ohms resistor of the SDMA clock.

-

The DSP has problems at 50 MHz.FIRST, do the work around above !

If the problem stills : DSP tolerence to the incoming clock. It may arrive at 50 MHz (can be verified with Anyplayer 2.21 and MP3 load with DSP + vumeters & DMA options ). The lentgh of the DSP clock wire is too important and signal is noised.

WORK AROUND : You must remove and cut this wire and install a new 50 MHz oscillator closed to the DSP. Be carefull : do not unsolder the 32 MHz OSC because it stills used by the SDMA ! The only problem with this solution is the DSP will never be clocked back to 32 MHz (CT60/16 or 030 modes). But there is no other solution to this problem...

Check with the finger the DSP temperature : if it is hot, add a small heatsink on it (with thermal glue).

- RESET

delay at POWER ON (all modes 030 & 060)Some ATX PSU may reveal this problem with a black screen.

WORK AROUND : Use a polarized capacitor of 22uF (or more) & 10V (or more) on C7 on the F30 motherboard near the RESET push button. Be carefull with the + & - pins (+ is on left to MIDI ports).